Premier Aluminum Llc Things To Know Before You Get This

According to a 2020 report, the demand for aluminum pass away casting climbed to virtually 6%, and it's approximated the manufacturing process will account for 55% of the vehicle segment. That claimed, It's crucial for suppliers to recognize the available aluminum die-casting firms to fulfill their needs.

We will likewise explain what they specialize in and the modern technologies they use to stay cost-efficient and create high-quality parts for various sectors. The business, founded in 1964, helps individuals in the transport industry create, style, and manufacture Light weight aluminum and Iron architectural components.

ConMet likewise features revolutionary modern technologies, including PreSet, Tru Turn, CastLite, and PreSet and also, which have actually transformed the industrial transportation sector by reducing fuel and upkeep prices and providing versatile, lightweight packaging. Dynacast International is yet another Light weight aluminum die-casting firm that tops our list for a great factor. The producing company serves a variety of industrial applications, consisting of electronic devices, automotive, aerospace, golf products, telecommunications, and far more.

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

From creating innovative design devices for light-weight to Value-Added Setting up. Headquartered in Henderson, Kentucky, Gibbs's key tasks include alloy growth and improvement of the spreading process. Broaching the spreading process. The business is rated as an international leader in both vertical and straight die spreading procedures, which aids fulfill the demands of its lasting tier-one and OEM clients.

The company specializes in manufacturing and developing a vast array of light weight aluminum components, from vehicle seating assistance and comfort systems to aerospace tubing and made assemblies. The company is also dedicated to providing high-performance parts that are adeptly engineered. In fact, it supplies high-volume components to a number of the heading Global OEMs in the mobile tools markets.

Our Premier Aluminum Llc Diaries

The surname in today's list is Alumcast, a leading Mexican company offering High Pressure Pass Away Casting (HDPC) and machining solutions to automobile, food, basic, and specialized sectors. Developed in 2018, this new-age factory materials highly completed light weight aluminum castings to Mexico and the U.S.A.. The company relies on leveraging modern tech and continual enhancement, and additionally pictures coming to be a market leader serving its customers with just the most effective.

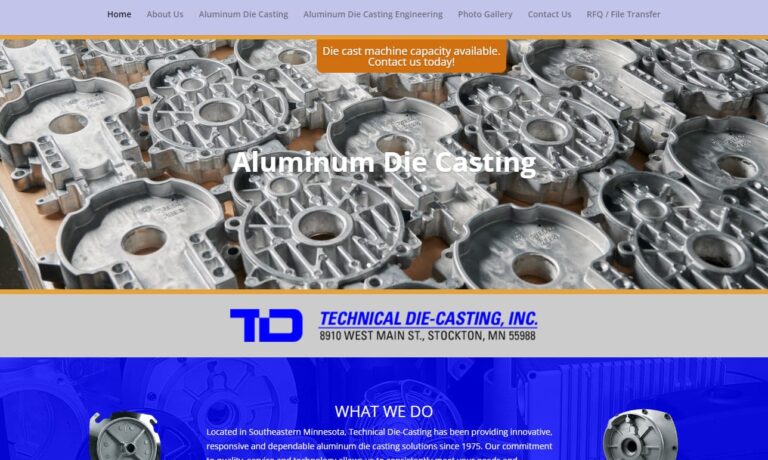

With a group of knowledgeable engineers and the most recent state-of-the-art equipment, our firm provides top quality parts across several industrial applications. Call us today, and allow's take your manufacturing game to the next degree!.

Usually, the further a design mistake is found in the developing cycle, the better its price. When tooling requires to be junked or reworked, the impact is obvious in prices and hold-ups. Nonetheless, reworking a die cast die also adds expense in reduced die life and potential unfavorable high quality effects.

The Facts About Premier Aluminum Llc Revealed

There are numerous model approaches from which to pick. The mechanical buildings of a plastic or machined part are fairly various from those of a die spreading.

We can then do numerous functional examinations. Properties are not comparable to die castings and parting line problems, and sometimes, the draft needed in a die spreading is not represented in a machined prototype. Sand spreading, investment spreading, and rubber plaster-mold castings are some gravity cast processes utilized for prototyping.

Contrasted to high-pressure die casting, sand cast models require thicker walls and bigger resistances, so features that could be "as-cast" in a die spreading may need to be machined in a sand spreading. These processes make use of lower-cost tooling than high-pressure die spreading but have a lot greater piece rates. These layout, residential property, and cost tradeoffs should be taken into consideration when examining the very best prototype method.

Prototype pass away casting dies can be produced in shorter lead times and at less price because they use standard componentslike an existing die baseand pre-hardened, uncoated tool steels that do not need post-machining heat treatment. Foundry near me. The tool will not run as efficiently as a typical manufacturing pass away, and flash will certainly need to be removed by hand as opposed to with a production trim die, but component costs will certainly be a lot less than for machined or gravity-cast models

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Light weight aluminum casting is a type of metalworking process that entails pouring liquid steel right into a mold or kind. Aluminum spreading might be a variation of this that utilizes only light weight aluminum and aluminum alloys as a result of the fluid steel that's put into the mold and mildew. Light weight aluminum castings are utilized to make complicated and detailed die casting components really check my blog efficiently.

Comments on “Getting My Premier Aluminum Llc To Work”